Reversing Sections

If you’ve purchased a command control system for your railroad, part of the reason was probably to eliminate the need for electrical blocks and the toggle switches to control them. You can control reverse sections manually, if you choose, but there are many ways to control them automatically. The goal of this piece is to apprise you of every option you have – you choose what is best for you.

Conventions

- When a loco is mentioned, it is assumed that it is a loco with a DCC decoder installed and running on a DCC-controlled layout, unless otherwise stated. Examples are an analog loco for a loco without a DCC decoder, or analog layout for a conventionally block-controlled layout.

- “DPDT” means double-pole, double-throw. Double-pole means that it has two independent circuits – one for each rail. Double-throw means that it has two positions of on – as opposed to one position for on, and one for off. A typical DPDT device has six connections for the circuitry to pass through – three for each pole, with each pole having a common (output), and two inputs. More about wiring these later.

Confusion about Reverse Loops

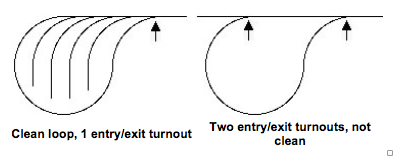

First, to dispel some mis-thinking of many people. With DCC, the polarity on the track has nothing to do with the direction of a loco. You can reverse the polarity on the rail while a loco is moving, and the loco won’t even flinch. So, if you choose to control a reverse section manually, you can simply use a DPDT toggle switch to control the polarity of the reverse section. You don’t need to ever reverse the polarity of the rest of the layout like you have to with conventional control. That said, let’s get on with it. There are basically four different ways to control polarity automatically – depending upon your track plan, ingenuity, attitudes, and budget. These are, in order of cost: slide switch connected to a turnout’s linkage, relay connected to a turnout’s electrical control system, Digitrax AR-1, Digitrax DB-210 or DCC Concepts PSX-1 only to mention a few, and various manufacturers’ auto-reversing boosters. This does not take turntable polarity into consideration, which will be discussed at length at the end of this piece. There are special situations, conditions, and other circumstances that will determine which of these will be best for you and your situation. First, we’ll discuss the conditions that must exist to be able to use the least expensive methods – slide switch and relay. Then we’ll get into everything there is to know about the other methods. If you have a “clean” reverse loop or a turn-around wye that has at least one dead-end leg, you can use either a DPDT slide switch or relay. A “clean” reverse loop is one that has only one turnout where the train can go in and out. This doesn’t mean that the loop can’t have other turnouts within it, to have yards, industry, or other sidings. It just means that there can’t be any other way out of the loop to get back to the mainline. | |

The examples at right show the difference.

Manual Controls

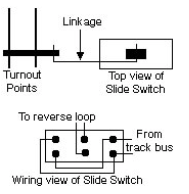

If you use manual hand throws on your turnouts, use a DPDT slide switch connected to the turnout linkage as illustrated here.

Latching Relays

If your turnout machine is a snap-type switch (double coil solenoid), you have to use a latching relay. If using a slow-motion machine, you can use a standard non-latching relay. A latching relay is one that can be triggered one way or the other, and it will stay that way even when the trigger power is removed. A non-latching relay is one that has two contacts normally closed, and the other two normally open. When power is applied to the coils, the contacts will reverse, and stay reversed as long as power is continued to be applied. Removal of power will allow the relay to reset to the original position.

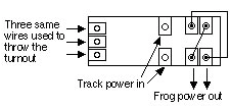

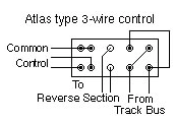

If your turnout machine is the snap-switch type (ones that get a pulse of power and then are removed), you need to use a latching relay. Atlas makes (and we sell) a latching relay (Snap Relay #200, illustrated in the diagram indicated at right) that is suitable for this purpose

Electronic stores usually carry a selection of other latching relays that will work. They’re typically wired like the DPDT slide or toggle switch, except that the common could be somewhere besides the middle two connectors. These relays are made with one or two control coils. To wire it like the Atlas, you need to get the two-coil type as illustrated in the diagram indicated at left.

If you have a dead-end leg on a turn-around wye, simply make the turnout to the dead-end leg the reverse section, and control the polarity of it with the slide switch or relay

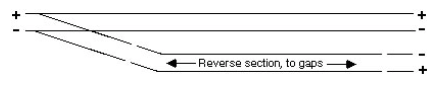

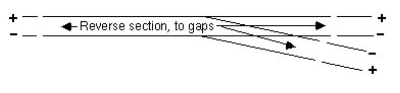

However, if you have a reverse section that is not in the form of a “clean” loop or dead-end leg (in other words, a reverse “section”), you must use either manual control, Digitrax AR-1 or DCC Concepts PSX-1 , or another manufacturer’s auto-reversing boosters. So, what are the differences? | |

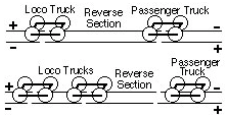

First, auto-reversing boosters require only two gaps at each end of the reverse section. Loy’s Toys ARSC requires multiple gapping, as illustrated here. Also, auto-reversing boosters have only two wires to connect to the reverse section (plus power into the booster), and Loy’s Toys ARSC has six (plus power from the track bus) – two for the reverse section, and two more for each detection section. However, there are other differences: When using auto-reversing boosters, the reverse section must be longer than the longest train that has power pickup trucks, such as lighted passenger cars, cabooses with power pickup for lighting, freight cars with power pickup for FREDs, sound, or other electrical needs. The reason for this is if you have a loco crossing the gaps at one end of the reverse section when a power pickup truck is crossing the gaps at the other end, you have a dead short, as illustrated here. | |

Auto-Reversing Boosters

First, there is only one company that make auto-reversing boosters: Digitrax. Digitrax boosters are designed to be triggered when there is any short circuit detected at all – even if it’s only one gap that has been shorted.

For a steam loco to trigger a Digitrax booster, the loco must be leaving a section of track that is also powered by a Digitrax booster. If you opt for this, you can use one Digitrax booster (set to not auto reverse) to power the entry and exit of all your reverse sections, then use another Digitrax booster to power all the reverse sections.

However, if you plan to be able to use more than one reverse section at a time, you could cause a short circuit. To avoid this, you must have one booster for each reverse section. However, the one booster (set to not auto reverse) for all the entries and exits will work just fine.

Wiring Hints

Now for some hints and tips about reverse sections. These tips have been derived from analyzing many track plans for many customers to figure out how to handle their reverse section problems.

- Draw your track plan in color. That is, draw your track plan, as one rail, in black. Then, draw the other rail in red. This will point out where you have a reverse polarity problem

- Many people have the urge to wire double mainlines with opposite polarity (one track East bound, the other West bound, as illustrated at right) because that’s what they’re used to when wiring block control

- But, if you wire them identically, as illustrated at right, you will eliminate any polarity problem at crossovers. If wiring them this way causes a polarity problem elsewhere, it will be easier to take care of it there than at the crossover

- If you have two tracks coming together, where the two tracks are of opposite polarities, you can install the reverse section in the merging track