How DCC Works

Digital Command Control consists of several parts: throttle, command station, booster, decoder, and a power supply to run it all. An optional throttle network can be added to have multiple walk-around throttles.

DCC System Diagram

Briefly (referring to the illustration at right):

- You use a throttle to tell the system what you want a train to do.

- The throttle sends the information to the command station.

- The command station makes a digital packet out of the information and sends it to the booster.

- The booster adds power to the digital packet and sends it out through the rail.

The decoders in all locomotives (even those that are not running) read all digital packets, and decipher them to get the address contained in the data packet. If the packet address matches the decoder address, the decoder uses the rest of the packet information. If the address does not match, the decoder continues doing whatever it was doing – whether it was running forward, backward, with or without lights, or nothing at all

DCC Basics

Before we go any further, there are three things that need to be made clear, so you don’t have a wrong pre-conception going in.

| |

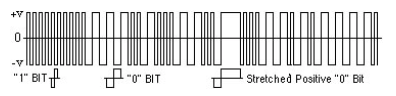

First, the DCC power and signal on the rails is square wave AC. Think of a normal DC computer signal square wave, as illustrated in the diagram at right, and double it – as explained below. | |

Computer signals like this are usually measured in milliamps, with a voltage swing from zero to 5V DC. This provides a good signal circuit, but could hardly power a train. So, the booster takes this signal, and amplifies it – voltage and amperage. What you wind up with is a digital signal with enough voltage and power to run trains. | |

Now for the AC part of the system. With DC power on the rail, a non-decodered loco would simply take off at full speed. So, the same exact signal that rises above zero is mirror-imaged to the negative side, making a square wave signal that swings from negative to positive – square wave AC – as illustrated in the diagram. | |

The actual voltage is dependent upon the booster you’re using, and at which scale you have it set to operate. Regardless, a short duration pulse represents a one (1), and a long pulse represents a zero (0). A group of eight pulses represents one byte of an information packet. | |

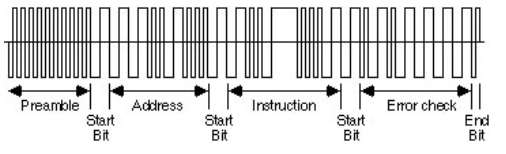

As illustrated in the diagram here, a basic packet contains a preamble of “1” bits, a “0” start bit, an address/data byte, a “0” start bit, an instruction byte, a “0” start bit, an error detection byte, and a “1” end bit – which leads into the preamble of “1” bits for the next packet. | |

As long as the duration of the negative (-) pulse matches the duration of each positive (+) pulse, a non-decodered loco will not move. It gets an instant of positive power trying to make the loco go forward, then gets an instant of negative power trying to make it go backwards. The result is a loco that sits there buzzing. (Note: a drop of Conductive Lube on the commutator can reduce this noise). “Zero stretching” is implemented to make the non-decodered loco go. That is, the zero (0) pulses are stretched longer on one side than the other. To make the loco go forward, the zeros on the positive side are stretched. This provides more positive power than negative. The loco still gets short pulses of negative power, but the longer positive pulses overpower the negative to make the loco go forward. Obviously, to make the loco go backwards, the negative zeros are stretched. As you’ve probably experienced, the faster the analog loco goes, the less it buzzes – because the longer periods of positive power reduces the number of AC pulses per second. While this analog loco is running, all DCC locos continue to run as if nothing else is happening to the signal. That’s because the decoders are designed to recognize short pulses as ones (1), and long pulses, no matter how long, as zeros (0). Stretched zeros are still read as zeros by decoders. If you want to install meters to monitor track power, you have to use AC volt and amp meters. However, even though AC meters work, they won’t be exactly accurate – because the typical AC meter is not designed for square wave. Even so, it will be accurate enough for general layout operation purposes. As for how decoders use square wave AC to control and power DCC locos, there are two parts to a decoder that use this power/signal: the control part, and the power part. Turning track power on also turns the decoder on. Even if the loco has never been addressed, the controlling part of the decoder starts reading the digital packets – all of them. Each packet is “decoded” to get the address. If that address matches, it acts upon the commands in the packet. If the address doesn’t match, it continues doing what the last packet for that loco said to do. That is, if the decoder has never been addressed, it continues doing nothing. But if the loco is running, or has a light or other function turned on, it continues passing power to the appropriate wires. | |

How Does the Decoder Get Power?

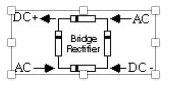

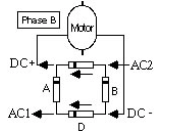

As for the power portion of the decoder, the first thing that has to be done is convert the AC power to DC. With AC, the current flows in one direction (phase A, below) for one pulse, then the other direction (phase B. below that) for one pulse, and so on, alternating back and forth – hence, alternating current. But, the decoder needs DC (direct current) to work. | |

Converting AC to DC is done with a device called a bridge rectifier, or with four diodes configured to make a bridge rectifier (a diode is a device that lets electricity flow in only one direction). So, when four diodes are configured as illustrated, the rail’s AC power is converted to DC. | |

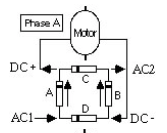

When AC flows into the AC1 connection (Phase A, at right), diode D blocks it in that direction, but Diode A allows it to go in that direction. Since Diode C blocks it in that direction, it has to go out DC+. It continues through the device being powered, back into to DC – through diode B and out the AC2 connection. | |

On the next cycle, Phase B, power flows into the AC2 connection through diode C, out DC+ through the device, then back in DC-, through diode D to go out the AC1 connection. | |

Since this alternating transition happens so fast, it effectively provides a constant flow of DC (direct current) power. This explains how AC is converted to DC, but doesn t explain how it can operate a motor in both directions. | |

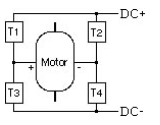

The motor is driven by power transistors. Transistors also allow power to go only in one direction. Consider this illustration: to make the loco go forward, transistors T1 and T4 are activated by the controlling circuitry of the decoder. T1 allows positive current to enter the positive terminal of the motor, while T4 connects the negative terminal of the motor to the negative terminal of the bridge rectifier. To make the motor go in reverse, transistors T2 and T3 are activated. | |

Speed Control

Since there is full voltage on the rails at all times, there is also full voltage available at the power transistors at all times. If the transistors are turned on to pass available voltage, the loco will take off at full speed. Unlike a water faucet, transistors are designed to pass full voltage, or no voltage. With a water faucet, if you want to pass 10 gallons per hour, you can simply turn the volume down and it will dribble 10 gallons per hour. But what if you have a valve that is either on or off. How would you get an even flow of water that would produce 10 gallons per hour? Simple, turn it on for one second, then off for a few. So, these power transistors are turned on (triggered) for a brief period of time, then turned off for a time depending on how fast the loco is to go.

The difference is that the transistors are turned on and off hundreds of times per second – so fast that the motor can’t respond instantaneously to each pulse. The motor has so much mass to it (including flywheels) that a single pulse can’t budge it. But, a whole lot of pulses can make it go. This is part of why locomotives run so much better on DCC than with DC analog.

A motor takes more voltage to get it started than it does to keep it going. For example, you’ve probably experienced increasing analog voltage to the tracks to a point where the loco lurches to a start, but can then reduce voltage to keep it going at a slower rate than it started. Well, DCC hits the motor with pulses of full voltage, so the full-voltage pulse can bump the motor to start, but doesn’t provide the power long enough to make it lurch.

Consider this: to make a loco run at 30% throttle with DC analog, you will be providing 30% of the available voltage all the time. But with DCC, you provide full voltage 30% of the time.